Inconel 718 Fin tubes, Inconel 718 Fin Tube Manufacturer, Inconel 718 Fin Tube Supplier, Inconel 718 Fin Tube Exporter, Inconel 718 Precision Tubing, Inconel 718 Small Diameter Tube , Inconel 718 Fin Tubes

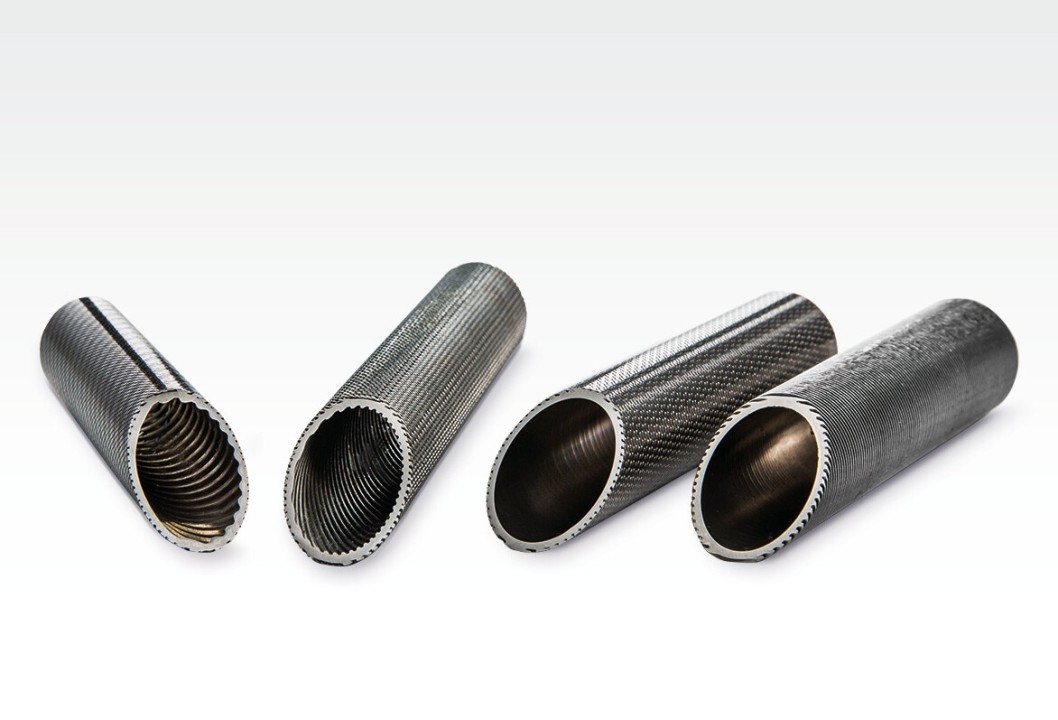

Inconel 718 fin tubes are specialized heat exchanger components made from a high-strength, nickel-based superalloy known for its exceptional resistance to heat and corrosion. These finned tubes are engineered for applications that demand performance in extreme environments, including high temperature, high pressure, and aggressive chemical conditions. The fins increase the surface area of the tube, significantly enhancing heat transfer efficiency while maintaining the strength and integrity of the base material.

The core material, Inconel 718 (UNS N07718), is a precipitation-hardened alloy composed mainly of nickel, chromium, iron, niobium, and molybdenum. It offers excellent tensile, fatigue, and creep-rupture strength up to temperatures around 700°C (1300°F). Inconel 718 also exhibits outstanding oxidation and corrosion resistance, even in harsh media such as acidic or chloride-rich environments. These properties make it ideal for long-term, high-stress operations with minimal degradation over time.

Inconel 718 fin tubes can be manufactured using various finning methods, including extrusion, welding, or embedding, depending on the application and thermal requirements. The fins are typically made from the same alloy to ensure uniform performance and thermal expansion. Fin density (fins per inch), height, and thickness are customizable to optimize thermal performance, allowing engineers to design systems that maximize efficiency in limited space or under constrained thermal load conditions.

These fin tubes are widely used in critical industries such as aerospace, power generation, nuclear, petrochemical, and offshore oil and gas. In aerospace, for instance, they are used in turbine cooling systems and jet engine components, where high temperature and mechanical stress are routine. In the energy sector, Inconel 718 finned tubes are used in heat exchangers, recuperators, and boiler systems exposed to high-pressure steam and corrosive gases, offering reliable service and extended operational life.

Specification of Inconel 718 Fin tubes

| Property | Specification / Range |

|---|---|

| Material Grade | Inconel 718 (UNS N07718) |

| Standards | ASTM B637, AMS 5662, AMS 5596 |

| Base Tube Outer Diameter | 6.35 mm to 38.1 mm (1/4" to 1-1/2") |

| Wall Thickness | 0.5 mm to 3 mm |

| Tube Length | Up to 20 meters (custom lengths available) |

| Fin Type | Extruded, Welded, or Embedded |

| Fin Height | 5 mm to 15 mm (customizable) |

| Fin Thickness | 0.3 mm to 1 mm |

| Fin Density | Up to 12 FPI (Fins Per Inch) or customized |

| Operating Temperature | Up to 700°C (1300°F) |

| Tensile Strength | ≥ 1,230 MPa (178 ksi) |

| Yield Strength (0.2% offset) | ≥ 1,030 MPa (150 ksi) |

| Elongation | ≥ 12% |

| Hardness | 331 HB max (after heat treatment) |

| Corrosion Resistance | Excellent – resistant to oxidation, acids, and chloride ions |

| Applications | Heat exchangers, boilers, condensers, aerospace, power plants |

| Surface Finish | Mill finish, polished, or coated (on request) |

| Testing & Certification | Hydrostatic, Eddy Current, PMI, NDT, per client specification |

Inconel 718 fin tubes offer a combination of durability, high heat transfer performance, and resistance to extreme operating conditions. Their robust mechanical properties reduce the risk of failure due to thermal cycling or chemical attack, resulting in lower maintenance costs and downtime. As a result, these tubes are considered a premium solution for systems that demand long service life, operational safety, and maximum efficiency in demanding thermal environments.

Chemical Composition of Inconel 718 Fin tubes

| Element | Weight % (Typical Range) |

|---|---|

| Nickel (Ni) | 50.0 – 55.0 |

| Chromium (Cr) | 17.0 – 21.0 |

| Iron (Fe) | Balance |

| Niobium (Nb) + Tantalum (Ta) | 4.75 – 5.50 |

| Molybdenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | ≤ 1.00 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Copper (Cu) | ≤ 0.30 |

| Boron (B) | ≤ 0.006 |

With a proven track record as a Inconel 718 Fin tubes exporter in over 30 countries, Sumer Metal Industries ensures global availability, third-party inspection support, and client-specific customization. Our wide export network combined with strict quality standards has made us a preferred choice for Inconel 718 tubing worldwide.

Specification of Inconel 718 Fin tubes

| Property | Specification / Range |

|---|---|

| Material Grade | Inconel 718 (UNS N07718) |

| Standards | ASTM B637, AMS 5662, AMS 5596 |

| Base Tube Outer Diameter | 6.35 mm to 38.1 mm (1/4" to 1-1/2") |

| Wall Thickness | 0.5 mm to 3 mm |

| Tube Length | Up to 20 meters (custom lengths available) |

| Fin Type | Extruded, Welded, or Embedded |

| Fin Height | 5 mm to 15 mm (customizable) |

| Fin Thickness | 0.3 mm to 1 mm |

| Fin Density | Up to 12 FPI (Fins Per Inch) or customized |

| Operating Temperature | Up to 700°C (1300°F) |

| Tensile Strength | ≥ 1,230 MPa (178 ksi) |

| Yield Strength (0.2% offset) | ≥ 1,030 MPa (150 ksi) |

| Elongation | ≥ 12% |

| Hardness | 331 HB max (after heat treatment) |

| Corrosion Resistance | Excellent – resistant to oxidation, acids, and chloride ions |

| Applications | Heat exchangers, boilers, condensers, aerospace, power plants |

| Surface Finish | Mill finish, polished, or coated (on request) |

| Testing & Certification | Hydrostatic, Eddy Current, PMI, NDT, per client specification |

🏭 Industry & Application

- ✅ Inconel 718 Fin Tubes for Medical Industry

- ✅ Inconel 718 Fin Tubes for Chemical Processing

- ✅ Inconel 718 Tubes for Fin Lines

- ✅ Inconel 718 Fin tubes for Gas & Liquid Flow

- ✅ Inconel 718 Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1:What is Inconel 718?

Inconel 718 is a high-strength, corrosion-resistant nickel-chromium alloy designed for high-temperature applications. It is precipitation-hardened and maintains excellent mechanical properties at temperatures up to 700°C (1300°F), making it ideal for demanding environments.

Q2:What are Inconel 718 fin tubes used for?

Inconel 718 fin tubes are primarily used in heat exchangers, condensers, boilers, and other thermal transfer systems that operate under high temperature, high pressure, or corrosive conditions. Typical industries include aerospace, power generation, chemical processing, and marine.

Q3:Why choose Inconel 718 for finned tubes?

Inconel 718 offers a combination of high tensile strength, excellent fatigue resistance, oxidation and corrosion resistance, and long service life. When combined with fins, it provides enhanced thermal efficiency while maintaining structural integrity in extreme environments.

Inconel 718 Fin tubes exporter

Inconel 718 Fin tubes Exporter in Oman, Inconel 718 Fin tubes Supplier in Oman, Inconel 718 Fin tubes in Oman, Inconel 718 Fin tubes Exporter in Saudi Arabia, Inconel 718 Fin tubes Supplier in Saudi Arabia, Inconel 718 Fin tubes in Saudi Arabia, Inconel 718 Fin tubes Exporter in UAE, Inconel 718 Fin tubes Supplier in UAE, Inconel 718 Fin tubes in UAE, Inconel 718 Fin tubes Exporter in Qatar, Inconel 718 Fin tubes Supplier in Qatar, Inconel 718 Fin tubes in Qatar, Inconel 718 Fin tubes Exporter in Kuwait, Inconel 718 Fin tubes Supplier in Kuwait, Inconel 718 Fin tubes in Kuwait, Inconel 718 Fin tubes Exporter in Bahrain, Inconel 718 Fin tubes Supplier in Bahrain, Inconel 718 Fin tubes in Bahrain, Inconel 718 Fin tubes Exporter in Egypt, Inconel 718 Fin tubes Supplier in Egypt, Inconel 718 Fin tubes in Egypt, Inconel 718 Fin tubes Exporter in South Africa, Inconel 718 Fin tubes Supplier in South Africa, Inconel 718 Fin tubes in South Africa, Inconel 718 Fin tubes Exporter in Kenya, Inconel 718 Fin tubes Supplier in Kenya, Inconel 718 Fin tubes in Kenya, Inconel 718 Fin tubes Exporter in Nigeria, Inconel 718 Fin tubes Supplier in Nigeria, Inconel 718 Fin tubes in Nigeria, Inconel 718 Fin tubes Exporter in Spain, Inconel 718 Fin tubes Supplier in Spain, Inconel 718 Fin tubes in Spain, Inconel 718 Fin tubes Exporter in Germany, Inconel 718 Fin tubes Supplier in Germany, Inconel 718 Fin tubes in Germany, Inconel 718 Fin tubes Exporter in USA, Inconel 718 Fin tubes Supplier in USA, Inconel 718 Fin tubes in USA, Inconel 718 Fin tubes Exporter in Canada, Inconel 718 Fin tubes Supplier in Canada, Inconel 718 Fin tubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More