Nickel 200 Fin Tubes, 200 Nickel Fin Tube Manufacturer, Nickel 200 Fin Tube Supplier, Nickel 200 Fin Tube Exporter, Nickel 200 Precision Tubing, Nickel 200 Small Diameter Tube , Nickel 200 Fin Tubes

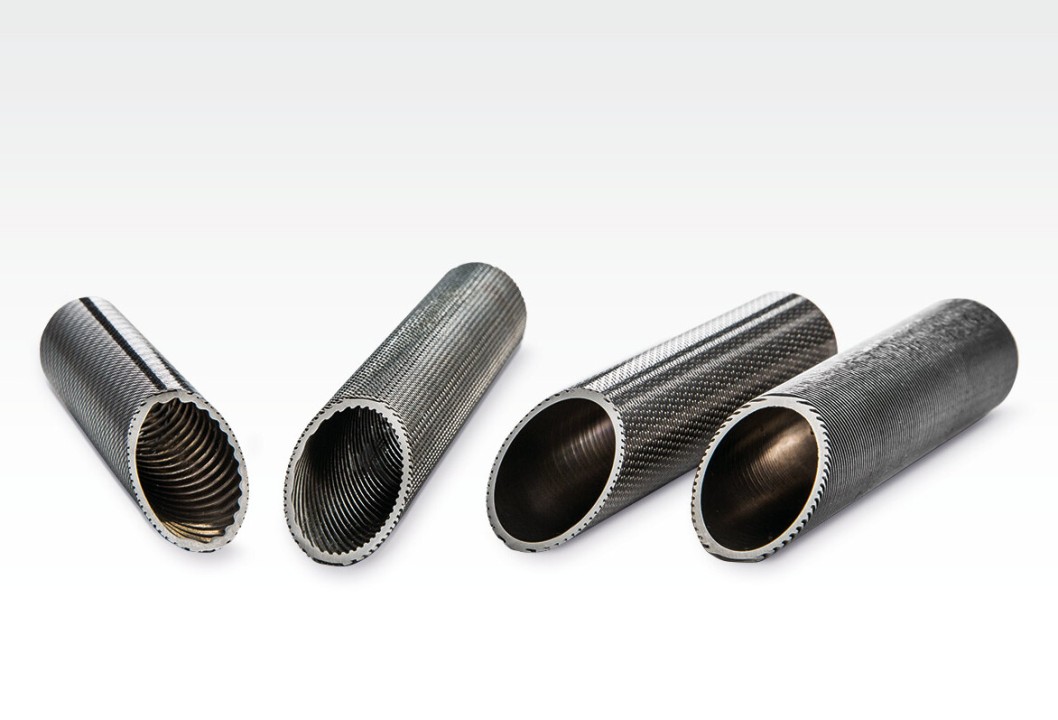

Nickel 200 fin tubes are a type of heat exchanger tubing made from commercially pure nickel (at least 99.6% pure) and designed with external fins to enhance heat transfer efficiency. These finned tubes are widely used in systems where efficient thermal exchange is required under demanding conditions. The base material, Nickel 200, is known for its excellent thermal conductivity, corrosion resistance, and mechanical strength, making it a preferred choice for industries that deal with highly corrosive environments or extreme temperatures.

One of the primary advantages of Nickel 200 fin tubes is their resistance to various corrosive agents, including caustic alkalis, neutral and alkaline salt solutions, and dry gases such as oxygen and chlorine. This corrosion resistance ensures long-term reliability in harsh service conditions. The addition of fins on the tubes increases the surface area available for heat transfer, allowing more efficient thermal exchange between the working fluid inside the tube and the environment or process fluid outside.

Nickel 200 also offers excellent mechanical properties at both high and low temperatures. These characteristics are crucial for applications such as chemical processing, power generation, and marine engineering, where components are exposed to fluctuating temperatures and pressures. The material maintains ductility and toughness even in cryogenic conditions, which makes Nickel 200 fin tubes suitable for heat exchangers in LNG and petrochemical plants.

From a fabrication perspective, Nickel 200 is relatively easy to form, weld, and machine, which facilitates the manufacturing of complex finned tube geometries tailored to specific customer needs. The fins can be manufactured through processes like extrusion, welding, or wrapping, depending on the thermal requirements and operational constraints. This adaptability enables engineers to optimize designs for efficiency, space-saving, and maintenance.

Specification of Nickel 200 Fin Tubes

| Property | Specification |

|---|---|

| Material Grade | Nickel 200 (UNS N02200, W. Nr. 2.4066) |

| Nickel Content (min.) | 99.6% |

| Tensile Strength | 380 MPa (55 ksi) minimum |

| Yield Strength (0.2% offset) | 105 MPa (15 ksi) minimum |

| Elongation | 45% minimum (in 2 inches) |

| Density | 8.89 g/cm³ |

| Melting Point | 1446°C (2635°F) |

| Thermal Conductivity | 90.7 W/m·K at 20°C |

| Coefficient of Expansion | 13.3 µm/m·°C (20–300°C) |

| Maximum Operating Temp. | 600°C (continuous service) |

| Tube Outer Diameter (OD) | 6 mm to 50.8 mm (custom sizes available) |

| Tube Wall Thickness | 0.5 mm to 3 mm (as per design requirements) |

| Fin Type | Integral, extruded, welded, or tension wound |

| Fin Height | Up to 15 mm (depending on design and fin type) |

| Fin Density | Up to 12 fins per inch (FPI), customizable |

| Fin Material | Same as base (Nickel 200) or dissimilar alloy if required |

| Standards | ASTM B161, B163, B730, ASME SB-161, SB-163 |

In conclusion, Nickel 200 fin tubes are a high-performance solution for industrial heat exchangers operating under corrosive and thermally demanding conditions. Their unique combination of corrosion resistance, thermal conductivity, and mechanical stability makes them a reliable and cost-effective choice in critical applications. Whether in chemical processing plants or offshore oil rigs, these finned tubes help ensure safe and efficient thermal operations.

Chemical Composition of Nickel 200 Fin Tubes

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Nickel (Ni) | 99.0 | — |

| Iron (Fe) | — | 0.40 |

| Manganese (Mn) | — | 0.35 |

| Copper (Cu) | — | 0.25 |

| Silicon (Si) | — | 0.35 |

| Carbon (C) | — | 0.15 |

| Sulfur (S) | — | 0.01 |

With a proven track record as a Nickel 200 Fin Tubes exporter in over 30 countries, Sumer Metal Industries ensures global availability, third-party inspection support, and client-specific customization. Our wide export network combined with strict quality standards has made us a preferred choice for Nickel 200 tubing worldwide.

Specification of Nickel 200 Fin Tubes

| Property | Specification |

|---|---|

| Material Grade | Nickel 200 (UNS N02200, W. Nr. 2.4066) |

| Nickel Content (min.) | 99.6% |

| Tensile Strength | 380 MPa (55 ksi) minimum |

| Yield Strength (0.2% offset) | 105 MPa (15 ksi) minimum |

| Elongation | 45% minimum (in 2 inches) |

| Density | 8.89 g/cm³ |

| Melting Point | 1446°C (2635°F) |

| Thermal Conductivity | 90.7 W/m·K at 20°C |

| Coefficient of Expansion | 13.3 µm/m·°C (20–300°C) |

| Maximum Operating Temp. | 600°C (continuous service) |

| Tube Outer Diameter (OD) | 6 mm to 50.8 mm (custom sizes available) |

| Tube Wall Thickness | 0.5 mm to 3 mm (as per design requirements) |

| Fin Type | Integral, extruded, welded, or tension wound |

| Fin Height | Up to 15 mm (depending on design and fin type) |

| Fin Density | Up to 12 fins per inch (FPI), customizable |

| Fin Material | Same as base (Nickel 200) or dissimilar alloy if required |

| Standards | ASTM B161, B163, B730, ASME SB-161, SB-163 |

🏭 Industry & Application

- ✅ Nickel 200 Fin Tubes for Medical Industry

- ✅ Nickel 200 Fin Tubes for Chemical Processing

- ✅ Nickel 200 Tubes for Fin Lines

- ✅ Nickel 200 Fin Tubes for Gas & Liquid Flow

- ✅ Nickel 200 Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1:What are Nickel 200 fin tubes used for?

Nickel 200 fin tubes are primarily used in heat exchangers, condensers, and evaporators, especially in industries dealing with highly corrosive environments. Common applications include chemical processing, marine systems, power plants, and food processing, where both corrosion resistance and efficient heat transfer are critical.

Q2:What makes Nickel 200 suitable for finned tubes?

Nickel 200 is a commercially pure nickel alloy (99.6% minimum nickel) known for its excellent corrosion resistance, especially in alkaline and reducing environments. It also has high thermal conductivity, good mechanical strength, and resistance to stress corrosion cracking, which makes it ideal for heat transfer applications.

Q3:How do fins enhance the performance of Nickel 200 tubes?

Fins increase the surface area of the tube, allowing more efficient heat transfer between the fluid inside the tube and the external environment. This means improved thermal performance without increasing the size or length of the tubes, which helps optimize space and efficiency in compact systems.

Nickel 200 Fin Tubes exporter

Nickel 200 Fin Tubes Exporter in Oman, Nickel 200 Fin Tubes Supplier in Oman, Nickel 200 Fin Tubes in Oman, Nickel 200 Fin Tubes Exporter in Saudi Arabia, Nickel 200 Fin Tubes Supplier in Saudi Arabia, Nickel 200 Fin Tubes in Saudi Arabia, Nickel 200 Fin Tubes Exporter in UAE, Nickel 200 Fin Tubes Supplier in UAE, Nickel 200 Fin Tubes in UAE, Nickel 200 Fin Tubes Exporter in Qatar, Nickel 200 Fin Tubes Supplier in Qatar, Nickel 200 Fin Tubes in Qatar, Nickel 200 Fin Tubes Exporter in Kuwait, Nickel 200 Fin Tubes Supplier in Kuwait, Nickel 200 Fin Tubes in Kuwait, Nickel 200 Fin Tubes Exporter in Bahrain, Nickel 200 Fin Tubes Supplier in Bahrain, Nickel 200 Fin Tubes in Bahrain, Nickel 200 Fin Tubes Exporter in Egypt, Nickel 200 Fin Tubes Supplier in Egypt, Nickel 200 Fin Tubes in Egypt, Nickel 200 Fin Tubes Exporter in South Africa, Nickel 200 Fin Tubes Supplier in South Africa, Nickel 200 Fin Tubes in South Africa, Nickel 200 Fin Tubes Exporter in Kenya, Nickel 200 Fin Tubes Supplier in Kenya, Nickel 200 Fin Tubes in Kenya, Nickel 200 Fin Tubes Exporter in Nigeria, Nickel 200 Fin Tubes Supplier in Nigeria, Nickel 200 Fin Tubes in Nigeria, Nickel 200 Fin Tubes Exporter in Spain, Nickel 200 Fin Tubes Supplier in Spain, Nickel 200 Fin Tubes in Spain, Nickel 200 Fin Tubes Exporter in Germany, Nickel 200 Fin Tubes Supplier in Germany, Nickel 200 Fin Tubes in Germany, Nickel 200 Fin Tubes Exporter in USA, Nickel 200 Fin Tubes Supplier in USA, Nickel 200 Fin Tubes in USA, Nickel 200 Fin Tubes Exporter in Canada, Nickel 200 Fin Tubes Supplier in Canada, Nickel 200 Fin Tubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More