Stainless Steel 202 Fin Tubes, SS 202 Fin Tubes, 202 Stainless Steel Fin Tube Manufacturer, SS 202 Fin Tube Supplier, SS 202 Fin Tube Exporter, Stainless Steel 202 Precision Tubing, SS 202 Small Diameter Tube ,SS 202 Instrumentation Tubes

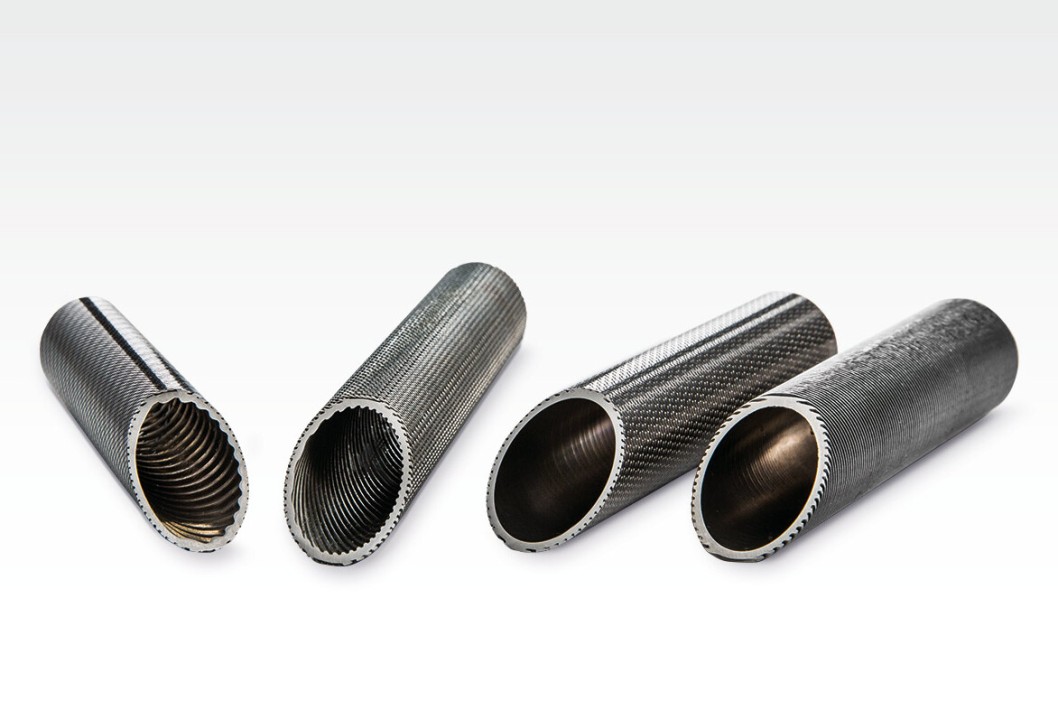

Stainless Steel 202 fin tubes are specialized heat exchanger components made from grade 202 stainless steel. These tubes are characterized by the presence of extended surfaces or "fins" that increase the surface area available for heat transfer. The use of SS 202 provides an economical alternative to more expensive stainless steel grades, while still offering good mechanical strength and corrosion resistance in moderate environments. These fin tubes are commonly used in heating, ventilation, and air conditioning (HVAC) systems, as well as various industrial heat exchangers.

SS 202 is a chromium-nickel-manganese austenitic stainless steel. It is less expensive than grades like SS 304 due to its lower nickel content and higher manganese levels. This composition makes it a cost-effective choice for applications where extreme corrosion resistance is not a primary requirement. In fin tube design, SS 202 provides sufficient resistance to oxidation and scaling at elevated temperatures, making it suitable for moderately aggressive conditions.

The finned design of these tubes significantly improves heat transfer efficiency. By increasing the outer surface area of the tube, the fins allow more heat to be exchanged between the fluid inside the tube and the environment outside. This makes SS 202 fin tubes ideal for use in air-cooled heat exchangers, boilers, economizers, and other thermal systems where efficient heat dissipation is critical. The fins can be welded or integrally formed, depending on the application and fabrication technique.

Durability and ease of fabrication are additional advantages of SS 202 fin tubes. The material is generally easier to machine and weld compared to higher alloyed stainless steels. However, care must be taken in high-chloride or marine environments, as SS 202 may be prone to localized corrosion such as pitting or stress corrosion cracking. For such applications, higher-grade stainless steels might be recommended.

Specification of Stainless Steel 202 Fin Tubes

| Property | Specification |

|---|---|

| Material Grade | Stainless Steel 202 |

| Standard Specifications | ASTM A213 / A269 / A554 (depending on application and form) |

| Chemical Composition | |

| – Chromium (Cr) | 17.0 – 19.0% |

| – Nickel (Ni) | 4.0 – 6.0% |

| – Manganese (Mn) | 7.5 – 10.0% |

| – Carbon (C) | ≤ 0.15% |

| – Silicon (Si) | ≤ 1.0% |

| – Phosphorus (P) | ≤ 0.06% |

| – Sulfur (S) | ≤ 0.03% |

| Mechanical Properties | |

| – Tensile Strength | ≥ 515 MPa (Min) |

| – Yield Strength (0.2% Offset) | ≥ 275 MPa (Min) |

| – Elongation | ≥ 40% |

| Fin Type | Integral or welded |

| Fin Height | 5 mm – 16 mm (customizable) |

| Fin Thickness | 0.3 mm – 1.0 mm |

| Tube Outer Diameter (OD) | 12 mm – 50.8 mm (customizable) |

| Tube Wall Thickness | 0.5 mm – 2.5 mm |

| Tube Length | Up to 12 meters or as per customer requirement |

| Operating Temperature | Up to 800°C (in non-corrosive environments) |

| Corrosion Resistance | Moderate (not recommended for marine or high-chloride environments) |

| Applications | HVAC, heat exchangers, boilers, dryers, air heaters, chemical & textile plants |

In summary, Stainless Steel 202 fin tubes offer a balanced combination of performance and affordability for a wide range of heat transfer applications. Their cost-effectiveness, good mechanical properties, and enhanced heat transfer capabilities make them a preferred choice in industries such as chemical processing, HVAC, and power generation—especially where budget constraints exist, and operating environments are not overly corrosive.

Chemical Composition of Stainless Steel 202 Fin Tubes

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 4.0 – 6.0 |

| Manganese (Mn) | 7.5 – 10.0 |

| Carbon (C) | ≤ 0.15 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.060 |

| Sulfur (S) | ≤ 0.030 |

| Nitrogen (N) | ≤ 0.25 |

| Iron (Fe) | Balance |

With a proven track record as a Stainless Steel 202 FinTubes exporter in over 30 countries, Sumer Metal Industries ensures global availability, third-party inspection support, and client-specific customization. Our wide export network combined with strict quality standards has made us a preferred choice for SS 202 tubing worldwide.

Specification of Stainless Steel 202 Fin Tubes

| Property | Specification |

|---|---|

| Material Grade | Stainless Steel 202 |

| Standard Specifications | ASTM A213 / A269 / A554 (depending on application and form) |

| Chemical Composition | |

| – Chromium (Cr) | 17.0 – 19.0% |

| – Nickel (Ni) | 4.0 – 6.0% |

| – Manganese (Mn) | 7.5 – 10.0% |

| – Carbon (C) | ≤ 0.15% |

| – Silicon (Si) | ≤ 1.0% |

| – Phosphorus (P) | ≤ 0.06% |

| – Sulfur (S) | ≤ 0.03% |

| Mechanical Properties | |

| – Tensile Strength | ≥ 515 MPa (Min) |

| – Yield Strength (0.2% Offset) | ≥ 275 MPa (Min) |

| – Elongation | ≥ 40% |

| Fin Type | Integral or welded |

| Fin Height | 5 mm – 16 mm (customizable) |

| Fin Thickness | 0.3 mm – 1.0 mm |

| Tube Outer Diameter (OD) | 12 mm – 50.8 mm (customizable) |

| Tube Wall Thickness | 0.5 mm – 2.5 mm |

| Tube Length | Up to 12 meters or as per customer requirement |

| Operating Temperature | Up to 800°C (in non-corrosive environments) |

| Corrosion Resistance | Moderate (not recommended for marine or high-chloride environments) |

| Applications | HVAC, heat exchangers, boilers, dryers, air heaters, chemical & textile plants |

🏭 Industry & Application

- ✅ SS 202 Fin Tubes for Medical Industry

- ✅ SS 202 Fin Tubes for Chemical Processing

- ✅ SS 202 Tubes for Instrumentation Lines

- ✅ Stainless Steel 202 Fin Tubes for Gas & Liquid Flow

- ✅ SS 202 Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1: What are Fin Tubes?

Fin tubes are tubes with extended surfaces (fins) to increase the surface area for heat transfer. They're used in heat exchangers to improve efficiency.

Q2: What is the maximum temperature SS 202 Fin Tubes can handle?

SS 202 can typically withstand temperatures up to 760°C (1400°F) in intermittent service, but for continuous high-temperature use, SS 304 or SS 316 is preferred due to better oxidation resistance.

Q3: Are SS 202 Fin Tubes corrosion-resistant?

Yes, but only in mild to moderate environments. Not suitable for marine or highly acidic/alkaline environments. For harsher conditions, SS 304 or SS 316 is recommended.

Stainless Steel 202 FinTubes exporter

Stainless Steel 202 FinTubes Exporter in Oman, Stainless Steel 202 FinTubes Supplier in Oman, Stainless Steel 202 FinTubes in Oman, Stainless Steel 202 FinTubes Exporter in Saudi Arabia, Stainless Steel 202 FinTubes Supplier in Saudi Arabia, Stainless Steel 202 FinTubes in Saudi Arabia, Stainless Steel 202 FinTubes Exporter in UAE, Stainless Steel 202 FinTubes Supplier in UAE, Stainless Steel 202 FinTubes in UAE, Stainless Steel 202 FinTubes Exporter in Qatar, Stainless Steel 202 FinTubes Supplier in Qatar, Stainless Steel 202 FinTubes in Qatar, Stainless Steel 202 FinTubes Exporter in Kuwait, Stainless Steel 202 FinTubes Supplier in Kuwait, Stainless Steel 202 FinTubes in Kuwait, Stainless Steel 202 FinTubes Exporter in Bahrain, Stainless Steel 202 FinTubes Supplier in Bahrain, Stainless Steel 202 FinTubes in Bahrain, Stainless Steel 202 FinTubes Exporter in Egypt, Stainless Steel 202 FinTubes Supplier in Egypt, Stainless Steel 202 FinTubes in Egypt, Stainless Steel 202 FinTubes Exporter in South Africa, Stainless Steel 202 FinTubes Supplier in South Africa, Stainless Steel 202 FinTubes in South Africa, Stainless Steel 202 FinTubes Exporter in Kenya, Stainless Steel 202 FinTubes Supplier in Kenya, Stainless Steel 202 FinTubes in Kenya, Stainless Steel 202 FinTubes Exporter in Nigeria, Stainless Steel 202 FinTubes Supplier in Nigeria, Stainless Steel 202 FinTubes in Nigeria, Stainless Steel 202 FinTubes Exporter in Spain, Stainless Steel 202 FinTubes Supplier in Spain, Stainless Steel 202 FinTubes in Spain, Stainless Steel 202 FinTubes Exporter in Germany, Stainless Steel 202 FinTubes Supplier in Germany, Stainless Steel 202 FinTubes in Germany, Stainless Steel 202 FinTubes Exporter in USA, Stainless Steel 202 FinTubes Supplier in USA, Stainless Steel 202 FinTubes in USA, Stainless Steel 202 FinTubes Exporter in Canada, Stainless Steel 202 FinTubes Supplier in Canada, Stainless Steel 202 FinTubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More