Stainless Steel 321 / 321h Instrumentation Tubes, SS 321/321 hInstrumentation Tubes, 321/321h Stainless Steel Instrumentation Tube Manufacturer, SS 321/321h Instrumentation Tube Supplier, SS 321/321h Instrumentation Tube Exporter, Stainless Steel 321/321h Precision Tubing, SS 321/321h Small Diameter Tube ,SS 321/321h Instrumentation Tubes

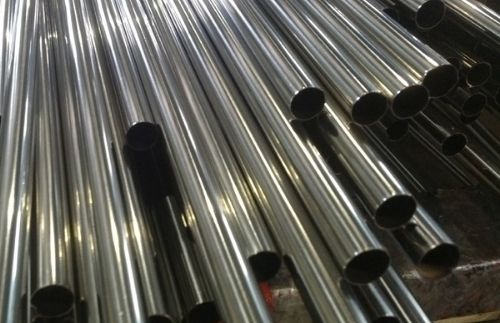

Stainless Steel 321 and 321H Instrumentation Tubes are specially engineered tubing products used in precision measurement and control systems, particularly in environments involving high temperatures and oxidizing media. These tubes are part of the austenitic stainless steel family and are stabilized with titanium, which helps prevent carbide precipitation during welding and high-temperature exposure. The “H” variant, Stainless Steel 321H, features a higher carbon content, enhancing its strength and creep resistance at elevated temperatures.

SS 321 is known for its excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range (427–816°C). It is suitable for long-term service in harsh thermal environments. SS 321H, due to its increased carbon content (0.04–0.10%), offers superior mechanical performance in high-heat applications like boilers, superheaters, and furnace components. Both alloys also maintain good ductility, weldability, and toughness, making them ideal for forming and fabrication.

321/321H instrumentation tubes are available in seamless and welded forms, with bright annealed, pickled, or polished surface finishes. They are manufactured to meet stringent international standards such as ASTM A213, ASTM A269, and ASTM A632. Tube dimensions typically range from 1/8” to 2” outer diameter, with various wall thicknesses available to support different pressure ratings. The smooth inner and outer surfaces ensure minimal fluid turbulence and excellent system cleanliness, which is essential in precision control systems.

These instrumentation tubes are widely used in oil and gas refineries, chemical and petrochemical plants, aerospace systems, power plants, and heat exchangers. Common applications include impulse lines, instrument panels, temperature and pressure measurement systems, and hydraulic and pneumatic control lines. The high-temperature capabilities of SS 321/321H make them suitable for continuous service in environments where other stainless steel grades like 304 or 316 may fail.

Specification of Stainless Steel 321 / 321hInstrumentation Tubes

| Property | Specification |

|---|---|

| Material Grades | Stainless Steel 321 (UNS S32100), 321H (UNS S32109) |

| Type | Titanium-stabilized Austenitic Stainless Steel |

| Standards | ASTM A213 / ASTM A269 / ASTM A632 / ASTM A789 / ASME SA213 / SA269 |

| Form | Seamless / Welded |

| Outer Diameter (OD) | 1/8" to 2" (3.18 mm to 50.8 mm) |

| Wall Thickness | 0.028" to 0.120" (0.7 mm to 3.0 mm) |

| Length | Up to 6 meters (20 ft) or custom cut-to-length |

| Surface Finish | Bright Annealed / Pickled / Polished |

| Tensile Strength (min) | 515 MPa (75 ksi) |

| Yield Strength (0.2%) | 205 MPa (30 ksi) |

| Elongation (min) | 35% |

| Hardness (max) | 95 HRB |

| Operating Temp (max) | Up to 870°C (1600°F) continuous service |

| Stabilizing Element | Titanium (Ti), min 5x C content |

| Corrosion Resistance | Excellent resistance to intergranular corrosion and oxidation |

| Weldability | Excellent – no post-weld heat treatment typically required |

| Certification | EN 10204 3.1 / 3.2 available upon request |

| Applications | Instrumentation lines, pressure systems, heat exchangers, refineries, power plants |

Stainless Steel 321 / 321H Instrumentation Tubes offer a reliable and long-lasting solution in demanding conditions. Their resistance to scaling, oxidation, and intergranular attack ensures consistent performance, while their mechanical strength allows them to withstand internal pressures and mechanical stress. The combination of corrosion resistance, thermal stability, and fabrication ease makes SS 321/321H an ideal material choice for critical instrumentation applications requiring both safety and durability.

Chemical Composition of Stainless Steel 321 / 321hInstrumentation Tubes

| Element | SS 321 (% by weight) | SS 321H (% by weight) |

|---|---|---|

| Carbon (C) | ≤ 0.08 | 0.04 – 0.10 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 | ≤ 0.030 |

| Silicon (Si) | ≤ 0.75 | ≤ 0.75 |

| Chromium (Cr) | 17.0 – 19.0 | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 12.0 | 9.0 – 12.0 |

| Titanium (Ti) | ≥ 5x C (typ. 0.20 – 0.70) | ≥ 4x C and ≤ 0.60 |

| Iron (Fe) | Balance | Balance |

With a proven track record as a Stainless Steel 321 / 321hInstrumentation Tubes exporter in over 30 countries, Sumer Metal Industries ensures global availability, third-party inspection support, and client-specific customization. Our wide export network combined with strict quality standards has made us a preferred choice for SS 321/321htubing worldwide.

Specification of Stainless Steel 321 / 321hInstrumentation Tubes

| Property | Specification |

|---|---|

| Material Grades | Stainless Steel 321 (UNS S32100), 321H (UNS S32109) |

| Type | Titanium-stabilized Austenitic Stainless Steel |

| Standards | ASTM A213 / ASTM A269 / ASTM A632 / ASTM A789 / ASME SA213 / SA269 |

| Form | Seamless / Welded |

| Outer Diameter (OD) | 1/8" to 2" (3.18 mm to 50.8 mm) |

| Wall Thickness | 0.028" to 0.120" (0.7 mm to 3.0 mm) |

| Length | Up to 6 meters (20 ft) or custom cut-to-length |

| Surface Finish | Bright Annealed / Pickled / Polished |

| Tensile Strength (min) | 515 MPa (75 ksi) |

| Yield Strength (0.2%) | 205 MPa (30 ksi) |

| Elongation (min) | 35% |

| Hardness (max) | 95 HRB |

| Operating Temp (max) | Up to 870°C (1600°F) continuous service |

| Stabilizing Element | Titanium (Ti), min 5x C content |

| Corrosion Resistance | Excellent resistance to intergranular corrosion and oxidation |

| Weldability | Excellent – no post-weld heat treatment typically required |

| Certification | EN 10204 3.1 / 3.2 available upon request |

| Applications | Instrumentation lines, pressure systems, heat exchangers, refineries, power plants |

🏭 Industry & Application

- ✅ SS 321/321h Instrumentation Tubes for Medical Industry

- ✅ SS 321/321h Instrumentation Tubes for Chemical Processing

- ✅ SS 321/321h Tubes for Instrumentation Lines

- ✅ Stainless Steel 321 / 321h Instrumentation Tubes for Gas & Liquid Flow

- ✅ SS 321/321h Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1: What is the difference between Stainless Steel 321 and 321H?

SS 321 and SS 321H are both titanium-stabilized stainless steels. The main difference is carbon content—321H has higher carbon (0.04–0.10%) to improve high-temperature strength and creep resistance, making it more suitable for service above 538°C (1000°F).

Q2:Why is titanium added to 321/321H tubes?

Titanium stabilizes the alloy by binding with carbon to prevent chromium carbide precipitation, which enhances resistance to intergranular corrosion, especially during welding or high-temperature service.

Q3:What industries typically use SS 321/321H instrumentation tubes?

These tubes are commonly used in chemical processing, oil and gas, power generation, aerospace, heat exchangers, and high-temperature instrumentation lines.

Stainless Steel 321 / 321hInstrumentation Tubes exporter

Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Oman, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Oman, Stainless Steel 321 / 321hInstrumentation Tubes in Oman, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Saudi Arabia, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Saudi Arabia, Stainless Steel 321 / 321hInstrumentation Tubes in Saudi Arabia, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in UAE, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in UAE, Stainless Steel 321 / 321hInstrumentation Tubes in UAE, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Qatar, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Qatar, Stainless Steel 321 / 321hInstrumentation Tubes in Qatar, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Kuwait, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Kuwait, Stainless Steel 321 / 321hInstrumentation Tubes in Kuwait, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Bahrain, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Bahrain, Stainless Steel 321 / 321hInstrumentation Tubes in Bahrain, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Egypt, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Egypt, Stainless Steel 321 / 321hInstrumentation Tubes in Egypt, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in South Africa, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in South Africa, Stainless Steel 321 / 321hInstrumentation Tubes in South Africa, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Kenya, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Kenya, Stainless Steel 321 / 321hInstrumentation Tubes in Kenya, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Nigeria, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Nigeria, Stainless Steel 321 / 321hInstrumentation Tubes in Nigeria, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Spain, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Spain, Stainless Steel 321 / 321hInstrumentation Tubes in Spain, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Germany, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Germany, Stainless Steel 321 / 321hInstrumentation Tubes in Germany, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in USA, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in USA, Stainless Steel 321 / 321hInstrumentation Tubes in USA, Stainless Steel 321 / 321hInstrumentation Tubes Exporter in Canada, Stainless Steel 321 / 321hInstrumentation Tubes Supplier in Canada, Stainless Steel 321 / 321hInstrumentation Tubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More