Stainless Steel 904L Fin Tubes, 904L Stainless Steel Fin Tube Manufacturer, SS 904L Fin Tube Supplier, SS 904LFin Tube Exporter, Stainless Steel 904L Precision Tubing, SS 904L Small Diameter Tube ,SS 904L Fin Tubes

Stainless Steel 904L Fin Tubes are specialized heat exchanger components known for their excellent corrosion resistance and mechanical strength. These tubes are made from 904L stainless steel, a low carbon, high-alloy austenitic stainless steel that contains high amounts of chromium, nickel, molybdenum, and copper. This unique composition provides superior resistance to harsh environments such as those containing sulfuric, phosphoric, and acetic acids, making them ideal for applications in chemical and petrochemical industries.

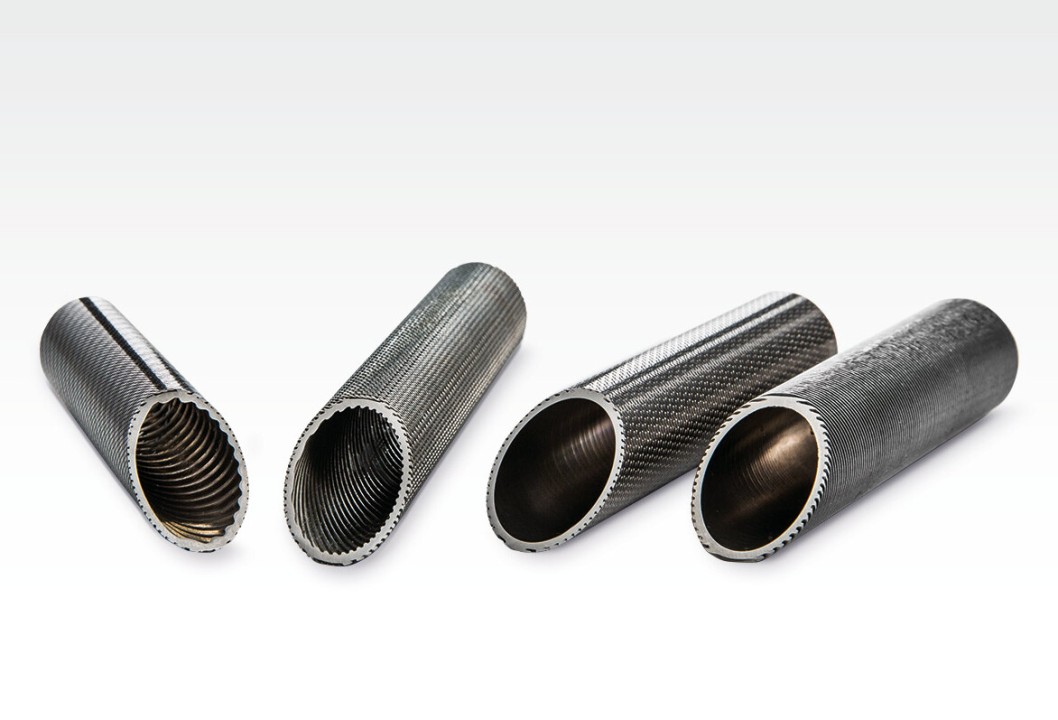

One of the key features of 904L fin tubes is their enhanced surface area, achieved by adding external fins to the base tube. This design significantly increases the efficiency of heat transfer between fluids, which is crucial in heat exchangers, condensers, and boilers. The fins can be formed by various methods such as extrusion, welding, or rolling, depending on the application requirements. The superior thermal performance, combined with excellent corrosion resistance, makes these fin tubes suitable for aggressive industrial environments.

904L stainless steel also exhibits excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. These properties make 904L fin tubes particularly valuable in marine applications, offshore oil and gas platforms, and in environments where chloride-induced corrosion is a concern. Their durability reduces the need for frequent maintenance and replacements, contributing to long-term cost efficiency.

Additionally, 904L fin tubes perform well at both high and low temperatures, maintaining structural integrity and thermal conductivity across a wide range of operating conditions. This versatility makes them suitable for heat exchangers in industries such as power generation, pulp and paper, pharmaceuticals, and air conditioning systems. Their ability to withstand extreme thermal cycling also enhances their reliability in dynamic process environments.

Specification of Stainless Steel 904L Fin Tubes

| Specification Parameter | Details / Range |

|---|---|

| Material Grade | Stainless Steel 904L (UNS N08904) |

| Chemical Composition (wt%) | C ≤ 0.02, Cr 19-23, Ni 23-28, Mo 4-5, Cu 1-2, Mn ≤ 2, Si ≤ 1, P ≤ 0.045, S ≤ 0.03 |

| Tube Outer Diameter (OD) | 15 mm – 76 mm (custom sizes available) |

| Tube Wall Thickness | 1.0 mm – 3.0 mm |

| Fin Height | 0.3 mm – 2.0 mm |

| Fin Pitch (Fin Spacing) | 1.0 mm – 5.0 mm |

| Fin Type | Helical, straight, serrated, embedded |

| Tensile Strength | ≥ 520 MPa |

| Yield Strength (0.2% offset) | ≥ 205 MPa |

| Elongation at Break | ≥ 30% |

| Hardness | Typically 150-200 HV |

| Operating Temperature Range | -196°C to 400°C |

| Corrosion Resistance | Excellent resistance to pitting, crevice, chloride, and acid corrosion |

| Surface Finish | Mill finish, polished, or customized |

| Applications | Heat exchangers, condensers, chemical processing, petrochemical, marine, power plants |

In summary, Stainless Steel 904L Fin Tubes offer a combination of corrosion resistance, thermal efficiency, and mechanical strength that make them a top choice for critical heat exchanger applications. Their longevity and performance in demanding conditions translate to reduced operational downtime and improved system efficiency, making them a valuable investment for industries requiring high-performance thermal solutions.

Chemical Composition of Stainless Steel 904L Fin Tubes

| Element | Typical Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.02 |

| Chromium (Cr) | 19.0 – 23.0 |

| Nickel (Ni) | 23.0 – 28.0 |

| Molybdenum (Mo) | 4.0 – 5.0 |

| Copper (Cu) | 1.0 – 2.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

In summary, Stainless Steel 904L Fin Tubes offer a robust solution for industries requiring high corrosion resistance, excellent strength, and precision performance. With their ability to perform under extreme environmental conditions, these tubes are a preferred choice for Fin and control systems in some of the world’s most demanding applications.

Specification of Stainless Steel 904L Fin Tubes

| Specification Parameter | Details / Range |

|---|---|

| Material Grade | Stainless Steel 904L (UNS N08904) |

| Chemical Composition (wt%) | C ≤ 0.02, Cr 19-23, Ni 23-28, Mo 4-5, Cu 1-2, Mn ≤ 2, Si ≤ 1, P ≤ 0.045, S ≤ 0.03 |

| Tube Outer Diameter (OD) | 15 mm – 76 mm (custom sizes available) |

| Tube Wall Thickness | 1.0 mm – 3.0 mm |

| Fin Height | 0.3 mm – 2.0 mm |

| Fin Pitch (Fin Spacing) | 1.0 mm – 5.0 mm |

| Fin Type | Helical, straight, serrated, embedded |

| Tensile Strength | ≥ 520 MPa |

| Yield Strength (0.2% offset) | ≥ 205 MPa |

| Elongation at Break | ≥ 30% |

| Hardness | Typically 150-200 HV |

| Operating Temperature Range | -196°C to 400°C |

| Corrosion Resistance | Excellent resistance to pitting, crevice, chloride, and acid corrosion |

| Surface Finish | Mill finish, polished, or customized |

| Applications | Heat exchangers, condensers, chemical processing, petrochemical, marine, power plants |

🏭 Industry & Application

- ✅ SS 904LFin Tubes for Medical Industry

- ✅ SS 904LFin Tubes for Chemical Processing

- ✅ SS 904L Tubes for Fin Lines

- ✅ Stainless Steel 904L Fin Tubes for Gas & Liquid Flow

- ✅ SS 904L Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1:What is Stainless Steel 904L Fin Tube?

Stainless Steel 904L Fin Tubes are heat exchanger tubes made from 904L stainless steel, featuring external fins to enhance heat transfer efficiency and corrosion resistance in harsh environments.

Q2: What industries use 904L Fin Tubes?

They are widely used in chemical processing, petrochemical, power generation, marine, and pharmaceutical industries due to their excellent corrosion resistance and thermal performance.

Q3:What makes 904L stainless steel special?

904L has high chromium, nickel, molybdenum, and copper content, giving it superior resistance to acid corrosion, pitting, and chloride stress corrosion cracking compared to other stainless steels.

Stainless Steel 904L Fin Tubes exporter

Stainless Steel 904L Fin Tubes Exporter in Oman, Stainless Steel 904L Fin Tubes Supplier in Oman, Stainless Steel 904L Fin Tubes in Oman, Stainless Steel 904L Fin Tubes Exporter in Saudi Arabia, Stainless Steel 904L Fin Tubes Supplier in Saudi Arabia, Stainless Steel 904L Fin Tubes in Saudi Arabia, Stainless Steel 904L Fin Tubes Exporter in UAE, Stainless Steel 904L Fin Tubes Supplier in UAE, Stainless Steel 904L Fin Tubes in UAE, Stainless Steel 904L Fin Tubes Exporter in Qatar, Stainless Steel 904L Fin Tubes Supplier in Qatar, Stainless Steel 904L Fin Tubes in Qatar, Stainless Steel 904L Fin Tubes Exporter in Kuwait, Stainless Steel 904L Fin Tubes Supplier in Kuwait, Stainless Steel 904L Fin Tubes in Kuwait, Stainless Steel 904L Fin Tubes Exporter in Bahrain, Stainless Steel 904L Fin Tubes Supplier in Bahrain, Stainless Steel 904L Fin Tubes in Bahrain, Stainless Steel 904L Fin Tubes Exporter in Egypt, Stainless Steel 904L Fin Tubes Supplier in Egypt, Stainless Steel 904L Fin Tubes in Egypt, Stainless Steel 904L Fin Tubes Exporter in South Africa, Stainless Steel 904L Fin Tubes Supplier in South Africa, Stainless Steel 904L Fin Tubes in South Africa, Stainless Steel 904L Fin Tubes Exporter in Kenya, Stainless Steel 904L Fin Tubes Supplier in Kenya, Stainless Steel 904L Fin Tubes in Kenya, Stainless Steel 904L Fin Tubes Exporter in Nigeria, Stainless Steel 904L Fin Tubes Supplier in Nigeria, Stainless Steel 904L Fin Tubes in Nigeria, Stainless Steel 904L Fin Tubes Exporter in Spain, Stainless Steel 904L Fin Tubes Supplier in Spain, Stainless Steel 904L Fin Tubes in Spain, Stainless Steel 904L Fin Tubes Exporter in Germany, Stainless Steel 904L Fin Tubes Supplier in Germany, Stainless Steel 904L Fin Tubes in Germany, Stainless Steel 904L Fin Tubes Exporter in USA, Stainless Steel 904L Fin Tubes Supplier in USA, Stainless Steel 904L Fin Tubes in USA, Stainless Steel 904L Fin Tubes Exporter in Canada, Stainless Steel 904L Fin Tubes Supplier in Canada, Stainless Steel 904L Fin Tubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More