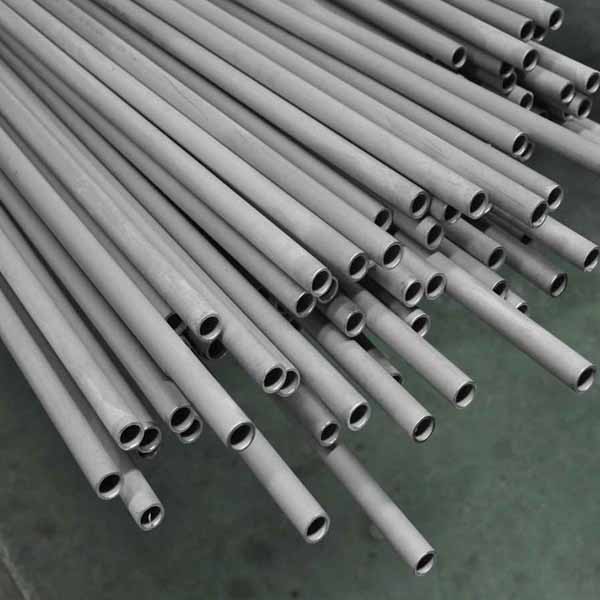

Super Duplex Steel S32750 Instrumentation Tubes, SS 32750 Instrumentation Tubes, 32750 Stainless Steel Instrumentation Tube Manufacturer, SS 32750 Instrumentation Tube Supplier, SS 32750 Instrumentation Tube Exporter, Stainless Steel 32750 Precision Tubing, SS 32750 Small Diameter Tube ,SS 32750 Instrumentation Tubes

Super Duplex Steel S32750 Instrumentation Tubes are specialized tubing solutions engineered to perform in the most demanding industrial environments. Made from the high-performance alloy UNS S32750, these tubes combine the superior mechanical strength and corrosion resistance of duplex stainless steels. The microstructure of S32750 features both austenitic and ferritic phases, providing excellent strength, toughness, and stress corrosion resistance that surpasses conventional stainless steels.

One of the defining advantages of Super Duplex S32750 is its exceptional resistance to localized corrosion, including pitting and crevice corrosion, especially in chloride-rich environments. This makes these instrumentation tubes ideal for offshore oil and gas applications, marine environments, and chemical processing plants where exposure to aggressive media is common. With high levels of chromium (24–26%), molybdenum (3–5%), and nitrogen, these tubes maintain their integrity even under high pressure and temperature conditions.

Instrumentation tubes are critical for controlling and monitoring systems in industrial operations. Super Duplex S32750 tubing is widely used in hydraulic and pneumatic control lines, chemical injection systems, and measurement equipment. Its excellent surface finish, tight dimensional tolerances, and resistance to corrosion make it a trusted choice for accurate data transmission and fluid flow control in mission-critical systems.

In addition to outstanding corrosion resistance, S32750 instrumentation tubes offer superior mechanical strength—twice that of standard austenitic stainless steels like 304 or 316. This allows for lighter wall thicknesses without compromising performance, reducing overall weight and cost in system design. The tubes are available in both seamless and welded forms and are manufactured in compliance with international standards such as ASTM A789, ASME SA789, and NACE MR0175/ISO 15156.

Specification of Super Duplex Steel S32750 Instrumentation Tubes

| Property | Specification |

|---|---|

| Material Grade | Super Duplex Stainless Steel UNS S32750 |

| Standard | ASTM A789 / ASME SA789 |

| Form | Seamless & Welded Instrumentation Tubes |

| Outer Diameter (OD) | 1.6 mm to 50.8 mm (custom sizes available) |

| Wall Thickness | 0.5 mm to 3.0 mm (customizable as per requirement) |

| Length | Single Random, Double Random, or Cut Lengths up to 6 meters |

| Tensile Strength (min) | 795 MPa (115 ksi) |

| Yield Strength (min) | 550 MPa (80 ksi) |

| Elongation (min) | 15% |

| Hardness (max) | 32 HRC |

| Density | 7.8 g/cm³ |

| Corrosion Resistance | Excellent resistance to pitting, crevice, and stress corrosion cracking |

| PREN (Pitting Resistance Eq. No.) | > 40 (indicates very high resistance to localized corrosion) |

| Chemical Composition (%): | |

| – Chromium (Cr) | 24.0 – 26.0% |

| – Nickel (Ni) | 6.0 – 8.0% |

| – Molybdenum (Mo) | 3.0 – 5.0% |

| – Nitrogen (N) | 0.24 – 0.32% |

| – Manganese (Mn) | ≤ 1.20% |

| – Carbon (C) | ≤ 0.030% |

| – Silicon (Si) | ≤ 0.80% |

| – Phosphorus (P) | ≤ 0.035% |

| – Sulfur (S) | ≤ 0.020% |

| Manufacturing Process | Cold Drawn / Bright Annealed / Solution Annealed |

| Surface Finish | Bright Annealed / Polished / Pickled & Passivated |

| Applicable Standards | ASTM A789, ASME SA789, NACE MR0175, ISO 15156 |

| Applications | Hydraulic & Pneumatic Systems, Chemical Injection, Instrumentation Lines, Offshore & Subsea Equipment |

Chemical Composition of Super Duplex Steel S32750 Instrumentation Tubes

| Element | Composition (% by weight) |

|---|---|

| Chromium (Cr) | 24.0 – 26.0% |

| Nickel (Ni) | 6.0 – 8.0% |

| Molybdenum (Mo) | 3.0 – 5.0% |

| Nitrogen (N) | 0.24 – 0.32% |

| Manganese (Mn) | ≤ 1.20% |

| Silicon (Si) | ≤ 0.80% |

| Carbon (C) | ≤ 0.030% |

| Phosphorus (P) | ≤ 0.035% |

| Sulfur (S) | ≤ 0.020% |

| Iron (Fe) | Balance |

Overall, Super Duplex Steel S32750 Instrumentation Tubes are a reliable and durable solution for industries that require high-performance materials with long service life. Whether used in subsea equipment, refineries, or desalination systems, these tubes deliver the necessary strength, corrosion resistance, and precision required to support critical instrumentation and control functions under extreme conditions.

Specification of Super Duplex Steel S32750 Instrumentation Tubes

| Property | Specification |

|---|---|

| Material Grade | Super Duplex Stainless Steel UNS S32750 |

| Standard | ASTM A789 / ASME SA789 |

| Form | Seamless & Welded Instrumentation Tubes |

| Outer Diameter (OD) | 1.6 mm to 50.8 mm (custom sizes available) |

| Wall Thickness | 0.5 mm to 3.0 mm (customizable as per requirement) |

| Length | Single Random, Double Random, or Cut Lengths up to 6 meters |

| Tensile Strength (min) | 795 MPa (115 ksi) |

| Yield Strength (min) | 550 MPa (80 ksi) |

| Elongation (min) | 15% |

| Hardness (max) | 32 HRC |

| Density | 7.8 g/cm³ |

| Corrosion Resistance | Excellent resistance to pitting, crevice, and stress corrosion cracking |

| PREN (Pitting Resistance Eq. No.) | > 40 (indicates very high resistance to localized corrosion) |

| Chemical Composition (%): | |

| – Chromium (Cr) | 24.0 – 26.0% |

| – Nickel (Ni) | 6.0 – 8.0% |

| – Molybdenum (Mo) | 3.0 – 5.0% |

| – Nitrogen (N) | 0.24 – 0.32% |

| – Manganese (Mn) | ≤ 1.20% |

| – Carbon (C) | ≤ 0.030% |

| – Silicon (Si) | ≤ 0.80% |

| – Phosphorus (P) | ≤ 0.035% |

| – Sulfur (S) | ≤ 0.020% |

| Manufacturing Process | Cold Drawn / Bright Annealed / Solution Annealed |

| Surface Finish | Bright Annealed / Polished / Pickled & Passivated |

| Applicable Standards | ASTM A789, ASME SA789, NACE MR0175, ISO 15156 |

| Applications | Hydraulic & Pneumatic Systems, Chemical Injection, Instrumentation Lines, Offshore & Subsea Equipment |

🏭 Industry & Application

- ✅ Super Duplex 32750 Instrumentation Tubes for Medical Industry

- ✅ Super Duplex 32750 Instrumentation Tubes for Chemical Processing

- ✅ Super Duplex 32750 Tubes for Instrumentation Lines

- ✅ Super Duplex Steel S32750 Instrumentation Tubes for Gas & Liquid Flow

- ✅ Super Duplex 32750 Tubes for Heat Exchangers

❓ Frequently Asked Questions (FAQs)

Q1:What is Super Duplex Steel S32750?

Super Duplex Steel S32750 (UNS S32750) is a high-performance stainless steel with a mixed microstructure of austenite and ferrite. It offers excellent mechanical strength and outstanding corrosion resistance, especially in harsh, chloride-rich environments.

Q2:Where are S32750 instrumentation tubes commonly used?

These tubes are widely used in industries such as oil & gas, petrochemical, offshore and subsea systems, chemical processing, power generation, and desalination plants—particularly in instrumentation and control lines, chemical injection systems, and hydraulic/pneumatic applications.

Q3: What sizes are available?

Common outer diameters range from 1.6 mm to 50.8 mm, with wall thicknesses from 0.5 mm to 3.0 mm. Tubes are available in standard lengths (e.g., 6 meters) or custom cut lengths on request.

Super Duplex Steel S32750 Instrumentation Tubes exporter

Super Duplex Steel S32750 Instrumentation Tubes Exporter in Oman, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Oman, Super Duplex Steel S32750 Instrumentation Tubes in Oman, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Saudi Arabia, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Saudi Arabia, Super Duplex Steel S32750 Instrumentation Tubes in Saudi Arabia, Super Duplex Steel S32750 Instrumentation Tubes Exporter in UAE, Super Duplex Steel S32750 Instrumentation Tubes Supplier in UAE, Super Duplex Steel S32750 Instrumentation Tubes in UAE, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Qatar, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Qatar, Super Duplex Steel S32750 Instrumentation Tubes in Qatar, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Kuwait, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Kuwait, Super Duplex Steel S32750 Instrumentation Tubes in Kuwait, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Bahrain, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Bahrain, Super Duplex Steel S32750 Instrumentation Tubes in Bahrain, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Egypt, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Egypt, Super Duplex Steel S32750 Instrumentation Tubes in Egypt, Super Duplex Steel S32750 Instrumentation Tubes Exporter in South Africa, Super Duplex Steel S32750 Instrumentation Tubes Supplier in South Africa, Super Duplex Steel S32750 Instrumentation Tubes in South Africa, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Kenya, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Kenya, Super Duplex Steel S32750 Instrumentation Tubes in Kenya, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Nigeria, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Nigeria, Super Duplex Steel S32750 Instrumentation Tubes in Nigeria, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Spain, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Spain, Super Duplex Steel S32750 Instrumentation Tubes in Spain, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Germany, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Germany, Super Duplex Steel S32750 Instrumentation Tubes in Germany, Super Duplex Steel S32750 Instrumentation Tubes Exporter in USA, Super Duplex Steel S32750 Instrumentation Tubes Supplier in USA, Super Duplex Steel S32750 Instrumentation Tubes in USA, Super Duplex Steel S32750 Instrumentation Tubes Exporter in Canada, Super Duplex Steel S32750 Instrumentation Tubes Supplier in Canada, Super Duplex Steel S32750 Instrumentation Tubes in Canada.

Categories

Countries We Export

At Sumer Metal Industries Pvt. Ltd., we follow a zero-defect policy by implementing stringent quality checks, using certified raw materials, and continuously improving our processes to deliver reliable and consistent tubing solutions

Read More